Futuristc,

floating

flatware

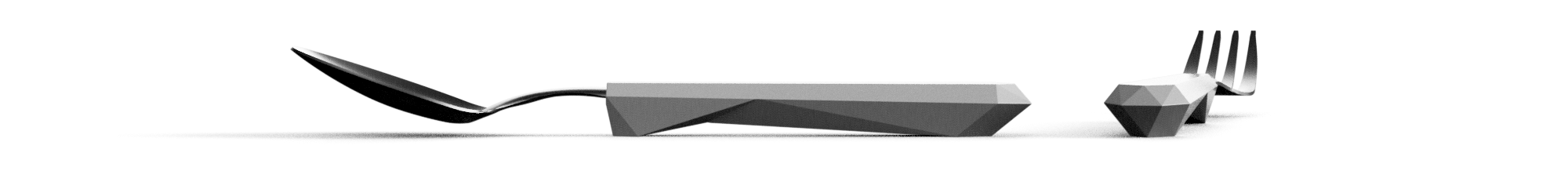

Inova Diamond is a flatware series designed for a large brazilian manufacturer. The Inova line bestows the feature of preventing the blade of the silverware from touching the surface beneath it. The Diamond models, thus, keep such feature while being reshaped with a completely different design language. The main goal of this project was to aid the manufacturer to position a simple, low cost polymer flatware as innovative and premium.

Designing the diamond

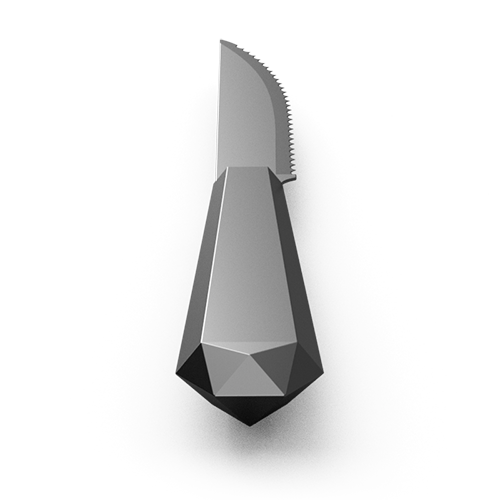

The geometric lines culminate in the diamond-shaped back of the grip. The reasoning behind choosing a mostly geometric, polygonal design language was to deviate from the previous Inova line, and most similar products for that matter, that employ curved, organic forms on the grips. It has a similar mass to its predecessor, not increasing manufacturing costs.

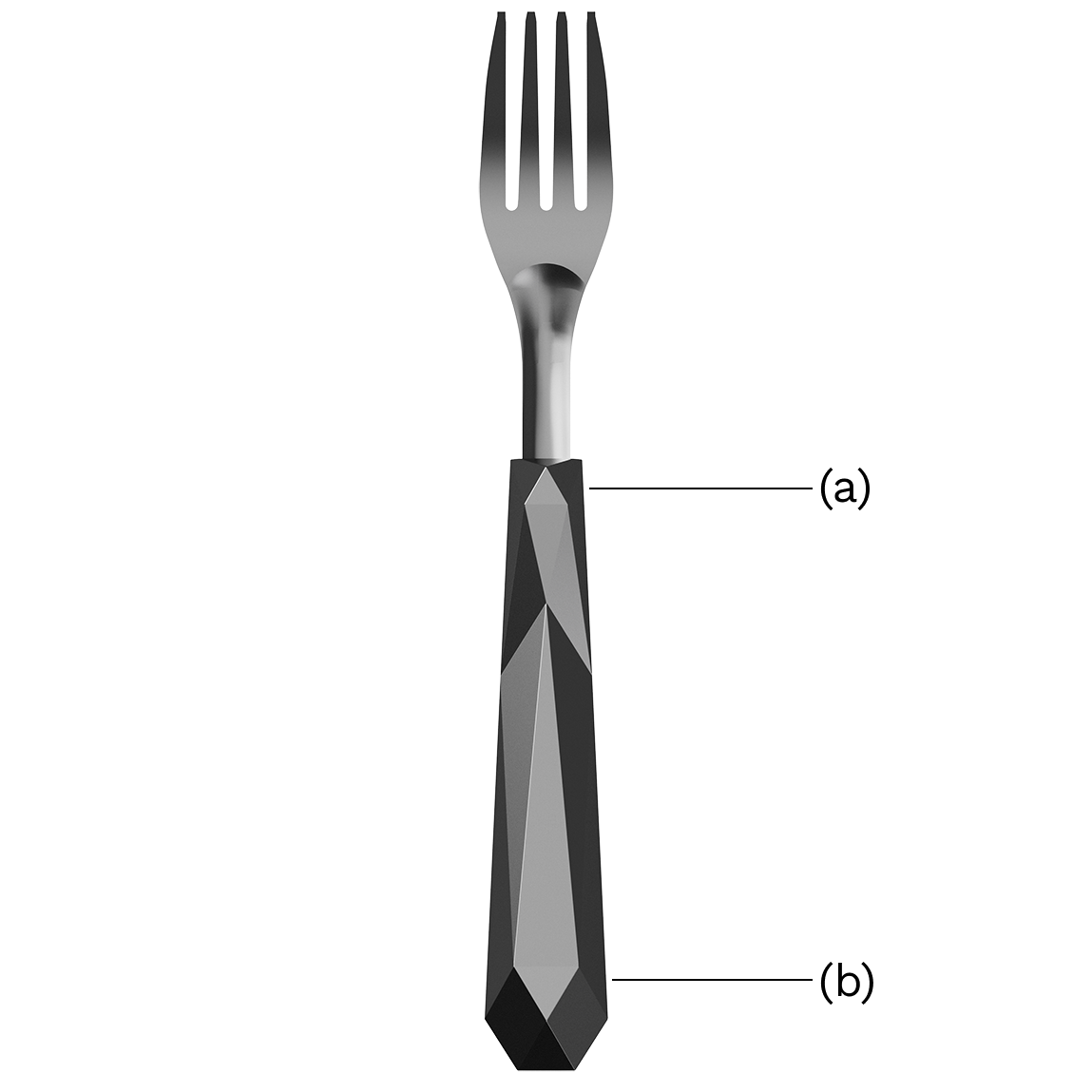

Organic doesn't necessarily mean "ergonomic", and vice-versa

During the ideation phase, the main theoretical touchstone was brazilian

ergonomist Itiro Iida's chapter on

grips and small utensils, where it's pointed out that while geometrically shaped grips

might not seem anatomical at first, they are well suited for longer handling periods

with low force exertion, because they allow for multiple hand positions (more

anatomically resembling grips, however, are better suited for shorter, higher force usage)

[1]. A live example of such concept is the chair _ONE, by Konstantin

Grcic.

The dimensions of faces (a) and (b) - the only in contact with the surface below -

were

finetuned through several rapid prototyping iterations, to find the optimal trade-off between

stability

and handling comfort.

Rapid prototyping

Prototyping was crucial to find a pleasant grip that still wouldn't tumble over The sequential iterations of the grip design (from top to bottom) were 3D printed in two halves, and had blades provided by the manufacturer attached to one end. The last one, in black, is an injection test. The prototypes were then brought to lunch at restaurants, to be tested.

Production

The manufactured product was showcased on the House and Gift Fair 2015, in São Paulo